Unlock Higher Yields with Modern Mineral Processing Equipment Technology

Modern mineral processing equipment technology offers industries a powerful way to extract more value from raw materials. By using advanced machines and upgraded systems, operations can increase efficiency, reduce losses, and improve the quality of final products. Older systems often face challenges like higher energy usage, lower recovery rates, and more downtime. With newer equipment, these problems can be minimized, leading to better returns and smoother processing.

Why Upgraded Technology Matters

Higher yields mean more output with less waste. Traditional equipment may not keep up with current demand or deliver optimal results. JXSC stands out in the industry with its wide range of mineral processing solutions tailored to diverse geological conditions. Modern mineral processing machines are engineered to meet rigorous industry needs, ensuring better recovery of valuable minerals from every load.

Benefits of Modern Mineral Processing Equipment:

- Improved Recovery Rates:

Advanced systems are designed to extract more minerals from the same volume of raw material. This increases overall production output.

- Energy Efficiency:

New machines are built to consume less energy, helping reduce operating costs while supporting sustainable practices.

- Precision and Control:

Modern equipment offers better control over process parameters, allowing consistent and high-quality outcomes.

- Durability and Low Maintenance:

Updated designs include wear-resistant parts and automated features that reduce manual intervention and machine downtime.

- Enhanced Safety Features:

Automated systems come with built-in safety protocols, minimizing the risk of accidents and ensuring compliance with regulations.

Key Equipment Innovations to Boost Yields:

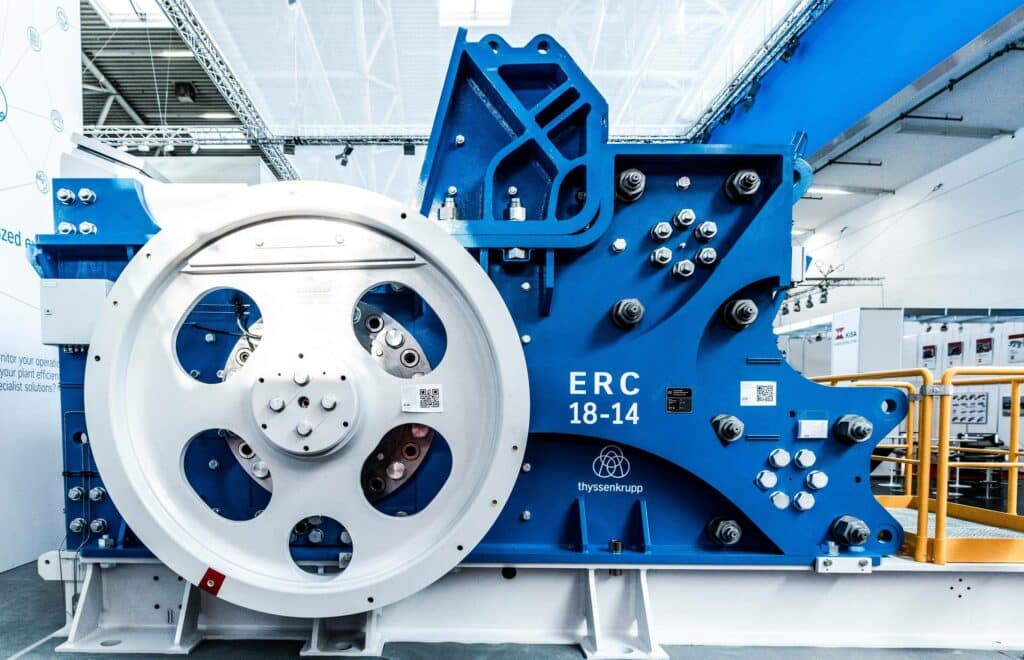

- Automated Crushing and Grinding Units:

These systems break down ore to optimal sizes, improving downstream processing performance and throughput.

- Advanced Separation Technologies:

Tools such as magnetic separators, flotation cells, and hydrocyclones enable efficient sorting and separation of minerals.

- Smart Screening Solutions:

High-capacity screens with real-time monitoring allow better classification and size control of processed materials.

- Digital Monitoring Systems:

Sensors and automation help track performance and detect issues early, leading to fewer disruptions and more consistent results.

Choosing the Right Equipment Strategy

To maximize yield, it is important to assess current operational needs and select machines that align with material type, volume, and end goals. While upfront investment may seem high, the long-term gains in production, efficiency, and reduced downtime offer strong returns.

Best Practices for Optimization:

- Conduct regular audits of current equipment and output

- Invest in modular systems that can adapt as needs grow

- Train operators to use new technology effectively

- Monitor output metrics regularly to spot inefficiencies

Unlocking higher yields is not just about increasing the volume of output it is about making every part of the process smarter, cleaner, and more reliable. With modern mineral processing equipment technology, businesses can meet demand, reduce waste, and improve bottom-line performance. Upgrading to the right technology ensures operations are not only productive but also prepared for future challenges.